What Happens If You Don’t Use a Needle Vibrator When Pouring Concrete?

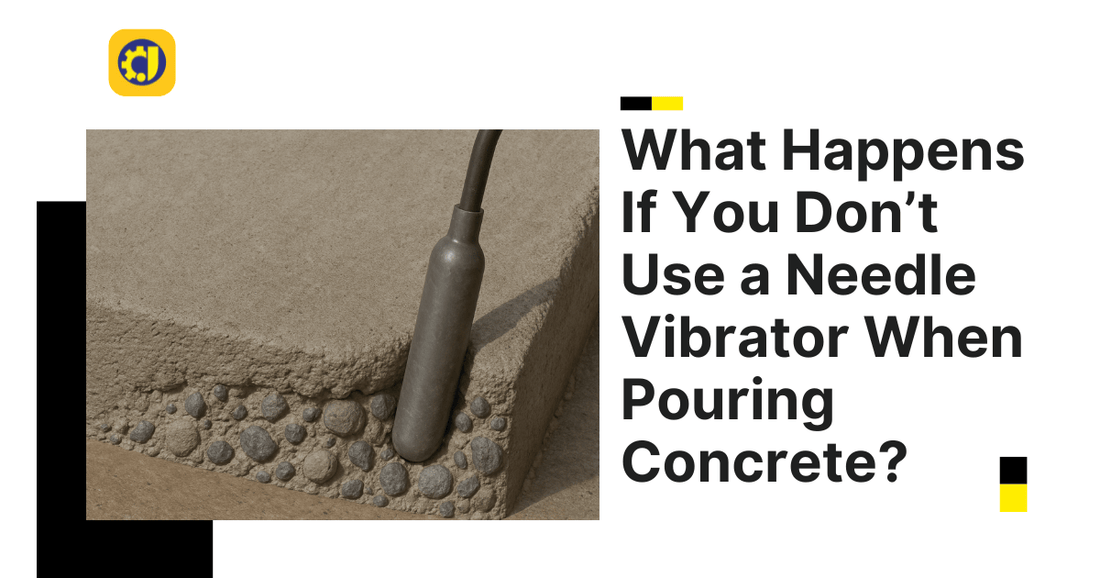

When pouring concrete, achieving the perfect finish and structural integrity is crucial. One of the most essential tools in this process is the concrete needle vibrator. While it may seem like an optional piece of equipment, not using a concrete needle vibrator can lead to various issues. In this blog post, we’ll explore the consequences of neglecting this essential tool.

The Importance of Concrete Needle Vibrators

A concrete needle vibrator helps remove air bubbles and ensures uniform compaction within the concrete mix. Without it, your concrete might not cure properly, which can lead to cracks, uneven surfaces, and even structural failure.

Problems That Arise When You Don’t Use a Needle Vibrator

1. Inadequate Compaction

Without a concrete needle vibrator, the concrete may not be compacted enough. This can cause air pockets, making the concrete weak and porous. The result? A less durable structure that can deteriorate faster over time.

2. Surface Imperfections

If the concrete is not vibrated properly, it can lead to uneven surfaces, which can be visually unappealing. Moreover, these imperfections can become entry points for water, causing corrosion in steel reinforcement.

3. Cracking and Shrinkage

When air pockets are trapped inside the concrete, it affects the curing process. This can cause uneven shrinkage, which leads to cracking. A concrete needle vibrator helps to evenly distribute the concrete mix, preventing these issues from arising.

4. Increased Risk of Segregation

Segregation happens when the heavier particles in the mix settle, leaving the lighter particles on top. This can result in weak spots in the concrete. A concrete needle vibrator prevents segregation by ensuring the materials are uniformly distributed throughout the mixture.

The Long-Term Consequences of Skipping Vibrators

1. Structural Weakness

Over time, poorly compacted concrete weakens and can cause serious structural issues. If you don’t use a concrete needle vibrator, you're compromising the strength of the entire structure. This is especially problematic for buildings, roads, and bridges that require high strength.

2. Increased Maintenance Costs

Concrete that hasn’t been properly compacted is more likely to develop cracks and damage. This leads to higher maintenance costs as repairs are needed more frequently. In the long run, this can be a significant expense.

Why You Should Use a Concrete Needle Vibrator

1. Enhances Concrete Durability

The primary function of a concrete needle vibrator is to enhance the durability of the concrete. By ensuring that the air bubbles are removed and the mix is compacted evenly, you’re improving the overall strength of the concrete.

2. Prevents Water Intrusion

Water is one of the most damaging elements to concrete. If your concrete has air pockets or is uneven, it can allow water to penetrate the surface. This can lead to rusting of reinforcement bars and other issues. A concrete needle vibrator helps ensure that water doesn’t get trapped in your concrete.

3. Improves Aesthetic Finish

Concrete that’s been vibrated with a needle vibrator has a smoother, more uniform surface. This leads to a better aesthetic finish, which is especially important in visible areas like floors, pavements, and countertops.

How to Use a Concrete Needle Vibrator

Using a concrete needle vibrator isn’t difficult, but it requires some attention to detail. The needle should be inserted into the freshly poured concrete and moved in and out at a consistent pace. This process should be repeated until the concrete reaches the desired level of compaction.

1. Insert the Needle Vertically

Start by inserting the needle vertically into the concrete. Make sure it goes deep enough to affect the entire mixture, but avoid hitting the bottom of the formwork.

2. Move the Needle Gradually

As the vibrator is running, slowly move it around to cover the entire surface. Ensure the vibrator stays in motion to avoid leaving air pockets in one area.

3. Check for Consistency

Once you’ve vibrated the concrete, check for uniformity. The surface should be smooth and free of any visible air pockets or holes. If any imperfections remain, continue vibrating until the mixture is even.

Conclusion: Don’t Skip the Concrete Needle Vibrator

In summary, not using a concrete needle vibrator during the pouring process can lead to a number of structural and aesthetic problems. From surface imperfections to long-term durability issues, the consequences can be severe. To ensure that your concrete pours are smooth, durable, and safe, always use a concrete needle vibrator. This tool is an investment in the longevity and strength of your concrete structures, making it an indispensable part of any construction project.