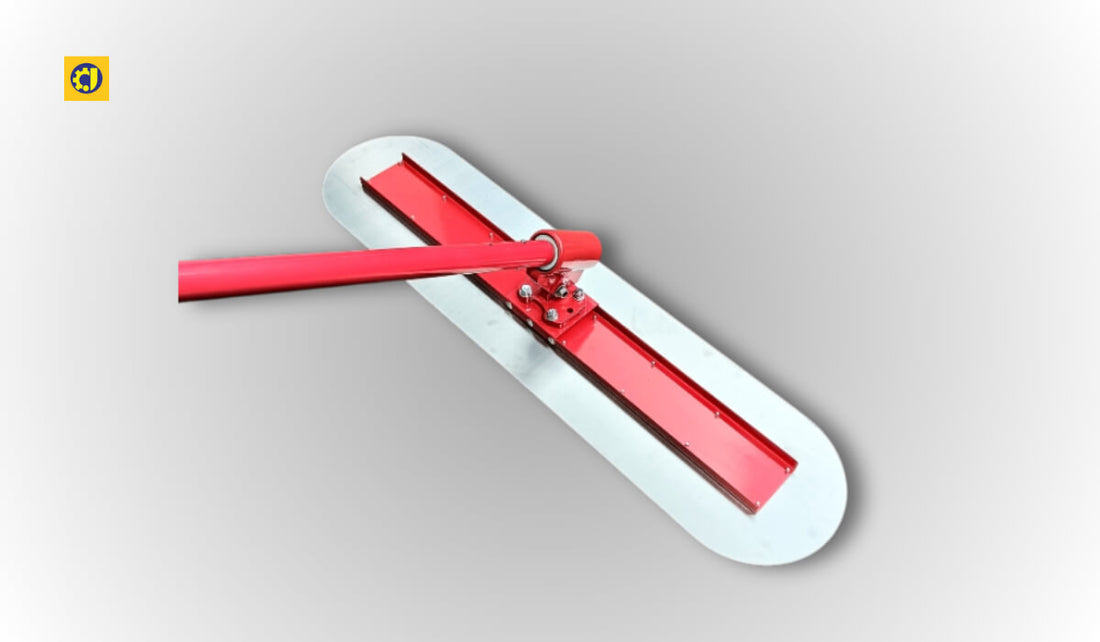

Bull float

Bull Float: Everything You Need to Know About This Concrete Tool

When working with concrete, having the right tools is essential. One such important tool is the Bull Float. Whether you are a contractor or a DIY enthusiast, understanding the purpose, types, and benefits of this tool can improve your concrete finishing work.

In this post, we will explore what a bull float is, its types, uses, pros and cons, and maintenance tips.

What Is a Bull Float?

A Bull Float is a tool used to smooth freshly poured concrete. It comes with a long handle and a flat, wide blade. This tool helps level the surface before the concrete starts setting. Unlike smaller finishing tools, a bull float covers a large area, making it perfect for bigger slabs like driveways, sidewalks, and floors.

Because it smooths out imperfections, it's often the first tool used after screeding.

The Need for Bull Floats in Concrete Work

Bull floats are needed to achieve a flat and smooth surface on wet concrete. When concrete is poured, it often has ridges and valleys from the screeding process. This tool helps reduce those flaws and pushes down large aggregates.

Without using a bull float, surfaces may dry unevenly or develop weak spots over time. Clearly, this simple tool plays a key role in long-lasting concrete jobs.

Common Uses of a Bull Float

The main use of a bull float is in the early stages of concrete finishing. It is used after screeding but before the final troweling. Here are common scenarios where it is used:

Leveling large concrete slabs

Preparing surfaces for troweling

Smoothing driveways and garage floors

Moreover, it helps in bringing the cream (cement and fine sand) to the surface, which is crucial for final finishing.

Types of Bull Floats We Offer

We offer two main types of bull floats: Aluminum Bull Floats and Stainless Steel Bull Floats. Each has its own advantages and is designed for specific needs.

Aluminum Bull Float

Aluminum floats are lightweight, which makes them easy to handle. They are ideal for small to medium-sized jobs and are a popular choice among beginners. However, they may wear down faster than steel.

Stainless Steel Bull Float

Stainless steel floats are more durable and provide a finer finish. Though they are heavier, they last longer and resist rust better than aluminum. This type is preferred for larger projects or frequent use.

>Buy Stainless Steel Bull Float.

Advantages of Using a Bull Float

Using a bull float offers several benefits:

Time-saving: It covers large areas quickly.

Improved finish: Results in a smoother surface.

Versatility: Works on various types of concrete jobs.

Reduces manual effort: Long handles reduce the need for bending and kneeling.

Therefore, it’s no surprise that it is a go-to tool for many contractors.

Disadvantages of Bull Floats

Despite their usefulness, bull floats have a few drawbacks:

Not ideal for small areas: The wide blade may not fit into tight spots.

Can trap air if overused: This may lead to surface issues.

Requires skill: Proper technique is needed to avoid over-finishing.

However, with a bit of practice, these issues can be managed easily.

How to Maintain Your Bull Float

Proper care extends the life of your bull float. After every use, it’s important to clean it thoroughly. Remove any concrete residue before it hardens. Store it in a dry place to avoid rust, especially for the steel version.

Also, inspect the handle joints and blades regularly. Tighten loose screws and replace worn parts as needed. This ensures consistent performance every time.

Final Thoughts

In summary, a Bull Float is a key tool in any concrete finishing process. It helps level and smooth wet concrete efficiently. Whether you choose an aluminum or stainless steel version, both types serve their purpose well.

Understanding how to use and maintain a bull float can lead to better results in your concrete projects. So, choose the right one for your job and get the smooth finish you’re aiming for.